1、The relevant certifications for Antimicrobial agents

USA:EPA,FDA,NSF,

Europe:BPD,RoHS,EFSA

2. Antibacterial mechanism of Antibacterial agents:

Many metal ions has antibacterial function. The bactericidal activity of metal ions in the following order: ag>hg>cu>cd>cr>ni>pb>co>zn>fe. Due to the highly toxic of Hg, CD, Pb and Cr, actually only AG, Cu and An are used as inorganic fungicide metals. And Ag’s bactericidal ability is much higher Cu and Zn.

Gradual release of silver ions happens because of the presence of water. .

Figure 1

Silver ions attached to the surface of the bacteria, and then into the bacteria, and react with the enzyme to generate sag, leading to bacterial death

Figure 2

3、Characteristics of antimicrobial agents

1)Flexibly designing the antimicrobial effect and life according to the use

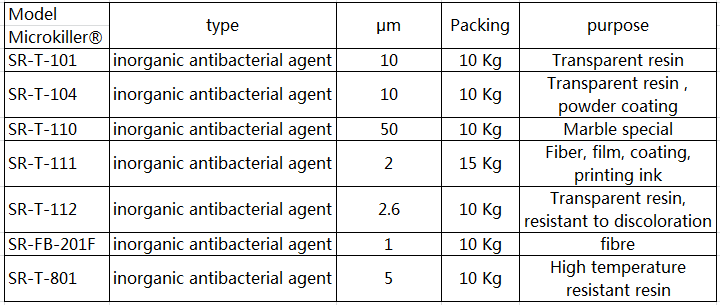

2)Various grades can be matched with all types of resins

3)The use of low concentration still has very good antibacterial effect

4)High transparency for resin to maintain, such as PP、PC、ABS、AS

5)Heat resistance is higher than 500 DEG C, adapt to all kinds of casting and spinning process.

6)Excellent performance after washing and hot water immersion

7)High security

4、Antimicrobial safety data:

1)No oral toxicity

Mice did not cause adverse reactions or death due to direct oral administration of 5000mg / kg

2)Basic skin irritation

In accordance with OECD (1981) in the chemical toxicity tests, conducted the skin irritation test on rabbits, no adverse reactions were found during and after the test

3)Heredity mutagenicity

Based on the n0.77 Bulletin of the Ministry of labor (9, L / 1988), the mutagenicity test was confirmed to be no increase in the reverse shift and the mutagenicity was negative

4)Skin sensibility

The method of maximizing skin sensitivity test, induced the 1% sensitive center on a l0 days old guinea pig, by 48-72 hours, proved no skin changes.